Application

The JBDW series microcomputer screen display automatic low temperature impact tester is used to measure the performance of metal materials against dynamic load impact at low temperature, so as to judge the properties of the material under dynamic load. This testing machine is a fully automatic control testing machine. The lifting, hanging, feeding, positioning, impact and temperature adjustments of the testing machine are all controlled by electrical, pneumatic and mechanical controls. It is easy to operate and has high work efficiency. It can be used after breaking the sample. The remaining energy automatically swings up and prepares for the next impact test.

Key Features

1. Fully automatic, pendulum rising, impact, sample feeding, position, free releasing is realized automatically by easy PC mouse click;sample feeding, auto position the sample; high efficiency;

2. The impact of the blade with screw mounting

With two pendulums (big and small), PC software to display the energy loss, impact tenacity, rising angle, test average value etc. test data and result, also the curve display available; with calculation and report printing function. The dial scale can show test results too.

3. Safety pin guaranties the impact action, standard protection shell to avoid any accident.

4. Pendulum will automatically rising and ready for next impact action after specimen breakout.

Specification

1. Impact energy: 150J, 300J

2. Range of plate-scale and sub- scale value

| Range of energy | 0-300J | 0-150J |

| Sub-scale value | 2J | 1J |

3. Pendulum moment(impact constant)

| Range of energy | 300J | 150J |

| Sub-scale value | 160.7695N.m | 80.3848N.m |

4. Angle of rising pendulum in advance: 150º

5. Distance from centre of pendulum and impacting point: 750mm

6. Impacting speed: 5.2m/s

7. Span of impact specimens supports: 40mm

8. Round corner of nipper jaw: R1-1.5mm

9. Round corner of impacting edge: R2-2.5mm

10. Capacity of specimen case: 10 pieces

11. Cooling way: compressors

12. Range of low temperature: 0-60°C

13. Precision of controlling temperature: fluctuation ±1.5°C grads 2°C

14. Speed of sending specimen:≤2S

15. Size of specimen: 10*10*55mm

16. Size of exterior: 1500mm*850mm*1340mm

17. Net weight of machine: 850kg

18. Electric power: three-phase AC 380V ± 10% 50Hz 5A

19. Environmental condition: non-corrosive media, no vibration, no strong electromagnetic field around.

Standard

ASTM E23, ISO148-2006 and GB/T3038-2002, GB/229-2007.

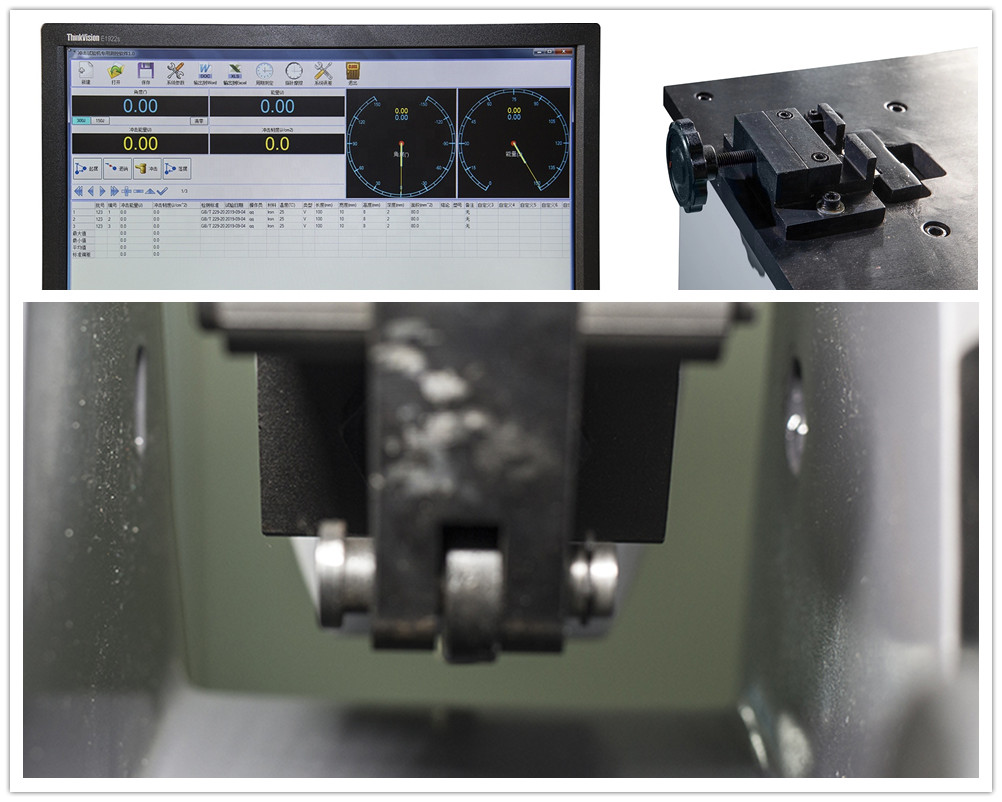

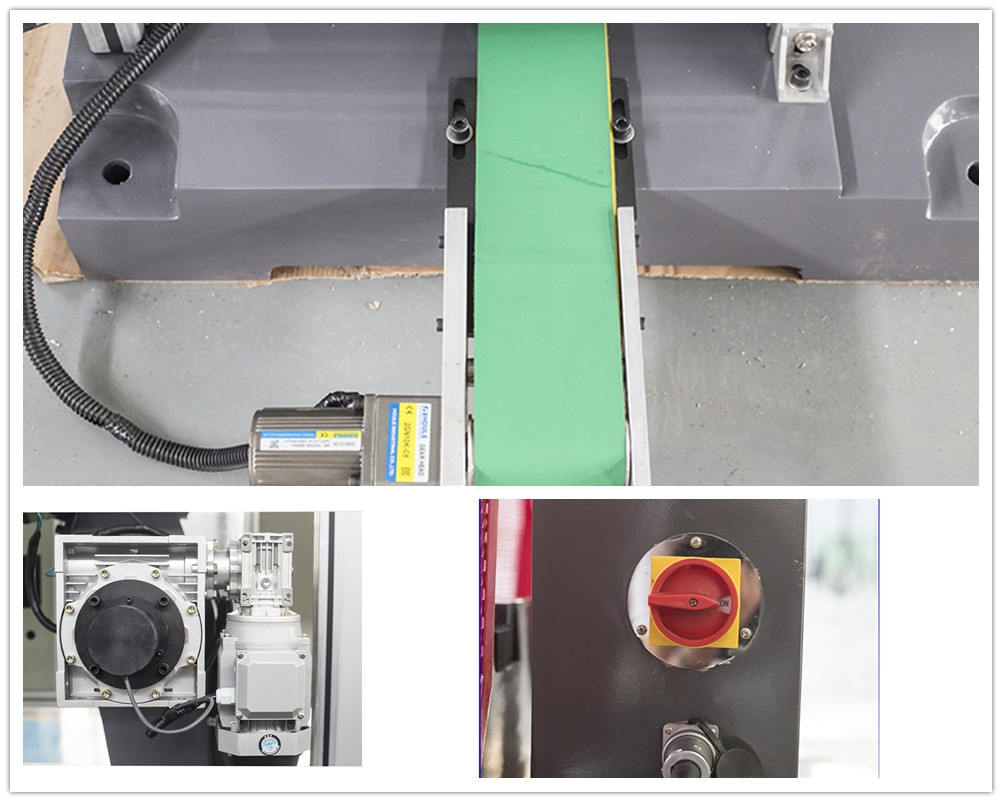

Real photos