Application

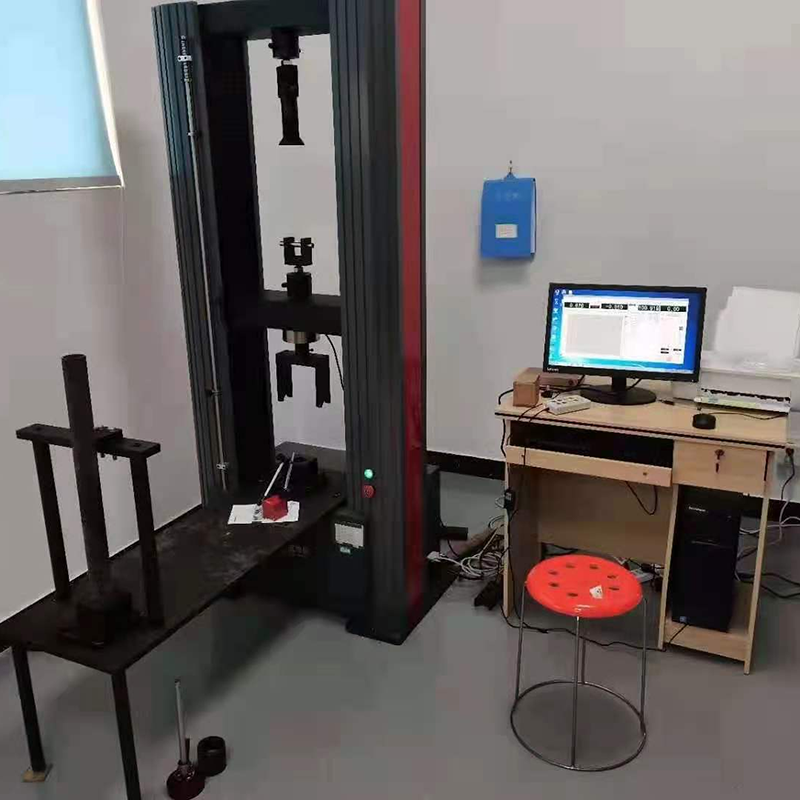

1. ZG-L series microcomputer controlled bowl button and safety net testing machine adopts advanced design concepts, beautiful appearance, convenient operation, stable and reliable performance. The computer directly controls the servo speed control system and the rotation of the servo motor through the fully digital control system (PCI card) developed by our company. The speed of the AC servo motor is decelerated by the deceleration system and transmitted to the precision ball screw pair to realize the beam rise, fall, test, etc. Action to complete the tensile, compression and other mechanical properties of the sample.

2. The professional software of the testing machine can automatically obtain the elastic modulus, yield strength, tensile strength, breaking strength, sample elongation, stiffness of the shock absorption system, constant force and deformation, constant deformation and force and other data and indicators, which can meet The closed-loop control mode of constant displacement, constant stress and constant deformation, and the test process can be programmed and controlled as required by the standard. The control and data processing of the test process by the computer control system meets the requirements of the corresponding national standards for metal materials and non-metal materials, and the test reports are diversified such as WORD, EXECEL and other methods.

3. This machine is pollution-free, low noise, high efficiency, and has a wide range of speed regulation. This machine is suitable for testing the mechanical properties of various metals, non-metals and composite materials, and fully meets the requirements of relevant national standards.

4. The machine is widely used in material inspection and analysis in construction materials, aerospace, machinery manufacturing, wire and cable, rubber and plastics, automobile manufacturing, shock absorption systems and other industries. It is used in scientific research institutions, universities, industrial and mining enterprises, technical supervision, Ideal testing equipment for commodity inspection and arbitration departments.

Specification

|

1 |

Maximum test force |

100kN |

|

2 |

Test machine level |

1.0 class |

|

3 |

Load measurement range |

1%~100%FS(1.0 class) |

|

4 |

Relative error of indication |

±1%(1.0 class) |

|

5 |

Test force resolution |

1/±500000FS(The full resolution remains unchanged) |

|

6 |

Deformation measurement range |

0.2%~100% |

|

7 |

Force control rate adjustment range |

0.005%~5%FS/S |

|

8 |

Force control rate control accuracy |

rate<0.05%FS,±1%; rate≥0.05%FS,±0.5%; |

|

9 |

Deformation rate adjustment range |

0.005~5%FS/s; |

|

10 |

Deformation rate control accuracy |

rate<0.05%FS/s,±1%; rate≥0.05%FS/s,±0.5%; |

|

11 |

Displacement rate adjustment range |

0.01~300mm/min; |

|

12 |

Displacement rate control accuracy |

±0.2%; |

|

13 |

Constant force, constant deformation, constant displacement control range |

0.5%~100%FS |

|

14 |

Constant force, constant deformation, constant displacement control accuracy |

setting≥10%FS,±0.5% setting<10%FS,±1% |

|

15 |

Effective test space |

400mm |

|

16 |

Spacing between upper and lower beams |

650mm |

|

18 |

voltage |

~220V±10% 50Hz |

|

19 |

Machine weight |

500kg |

Key Features

1. The testing machine has no pollution, low noise, convenient operation and high efficiency;

2. The main machine shell adopts aluminum alloy shell, which is beautiful and generous;

3. The main unit is an overall floor-standing vertical structure, with high rigidity, stable performance and beautiful appearance;

4. Stretching and compression are realized in separate double spaces, avoiding the tediousness of replacing different test attachments in the same space;

5. The mainframe structure is sturdy and durable. The thick ball screw and guiding light rod, thickened beam and base constitute a strong rigid frame, which can meet the test of high-strength materials;

6. The upper and lower beams of the main machine and the worktable are processed synchronously to ensure excellent alignment. When the axial test is carried out, to ensure that the lateral force of the sample under the load is minimally affected, and accurate stress and strain results can be obtained. ;

7. The screw is a precision ground ball screw, and the screw nut is made of cast copper material, which is wear-resistant. The friction coefficient of the screw pair is small, the transmission efficiency is high, the precision is high, and the strength is high;

8. The reduction mechanism composed of a reducer, a synchronous toothed belt, and a precision ball screw pair has a simple structure to ensure the synchronous movement of the screw and help the system to center;

9. High-power motors with reserve power, preloaded bearings, low-tension synchronous toothed belts, and precision ball screw pairs can minimize the energy stored during the test process, so as to obtain better test performance and obtain better performance. It is the precise modulus and strain value. It is particularly effective when testing high-strength materials, such as aerospace composite materials and metal alloys;

10. Using AC servo motor and speed control system to control the test process, the control accuracy is high, stable, high-efficiency, low noise (low speed

Basically no noise at the time). And the control speed range is greatly widened (0.001-500mm/min), which is not only beneficial to the low-speed test of conventional materials (metal, cement, concrete, etc.), but also to the high-speed test of non-metallic materials (rubber, film, etc.). It is convenient to quickly adjust the test space when there is no load, and save auxiliary test time. The test speed meets the current requirements for the test speed of all conventional metal and non-metal materials in China;

11. Multi-specification fixture adapters and multiple accessory options can realize the mechanical test of a variety of materials, giving the equipment more test functions;

12. The concentric ring and positioning pin fully ensure the upper and lower coaxiality of the test fixture, so that the specimen is fully stressed in the axial direction;

13. Force measurement adopts imported high-precision spoke load cell with high comprehensive accuracy, high sensitivity and good repeatability. After random calibration, the test is not affected by external forces, which can ensure the accuracy of the test process and parameters;

14. The force direction of the sensor is the same during tensile, compression and other tests, and the calibration and calibration are simple and convenient;

15. Sensors of different specifications can be configured according to requirements, which greatly widens the test range to meet the measurement requirements of different test loads;

16. The deformation measurement adopts high-precision electronic extensometer or large deformation extensometer;

17. Displacement measurement is realized by the built-in displacement measurement system of AC servo motor;

18. The safe portable wireless remote control creatively integrates multiple functions, which is very convenient to use and operate, and greatly simplifies the strong current configuration, reduces the use of discrete electrical components, and effectively reduces the electrical failure rate;

19. It can realize the fast/slow lifting adjustment of the beam when the specimen is clamped, and the operation is flexible and can be switched at will;

20. It has the function of returning to the initial position after the test, which is efficient and fast;

21. It has perfect limit protection function, overload and overcurrent protection, test break automatic shutdown and other functions, reliable and safe;

22. Equipped with a high-performance intelligent all-digital independent controller and adopts all-digital PID adjustment to realize a hardware-based parallel sampling mode, which can realize multiple closed-loop control modes such as constant rate stress, constant rate displacement, and constant rate strain. And can realize smooth switching between different control modes without disturbance;

23. The measurement and control system is equipped with a multi-function test software package, and adopts VXDs high-speed data acquisition technology to achieve high-speed acquisition of multi-channel data; the test results can be analyzed and processed according to the requirements of different test methods, and the man-machine interactive programming control function is provided to facilitate the addition of new tests. Standard; It has powerful graphics operation functions, can display test curves and test data in real time, has curve zoom, graphics zoom, interception functions, and cursor following display functions. It has the storage function of complete test curves and test data; it has the functions of single-piece test report output and batch test report output and printing;

24. With network interface, it can realize data networking and remote control functions;

25. The equipment is cost-effective. The quality of imported equipment, the price of domestic equipment.

Standard

1. GB/T228-2002 "Metal Material Room Temperature Tensile Test Method"

2. GB/15831-2006 steel pipe scaffolding fasteners

3. GB/T5725-2009 "Safety Net"

4. GB/T15831-2006 "Steel Pipe Scaffolding Fasteners"

5. GB24911-2010 Bowl-and-mouth fastener detection standard

6. GBT 6096-2009 safety belt test method, GB 5725-2009 safety net and other hundreds of standards, and standard methods can be customized for users.