Application

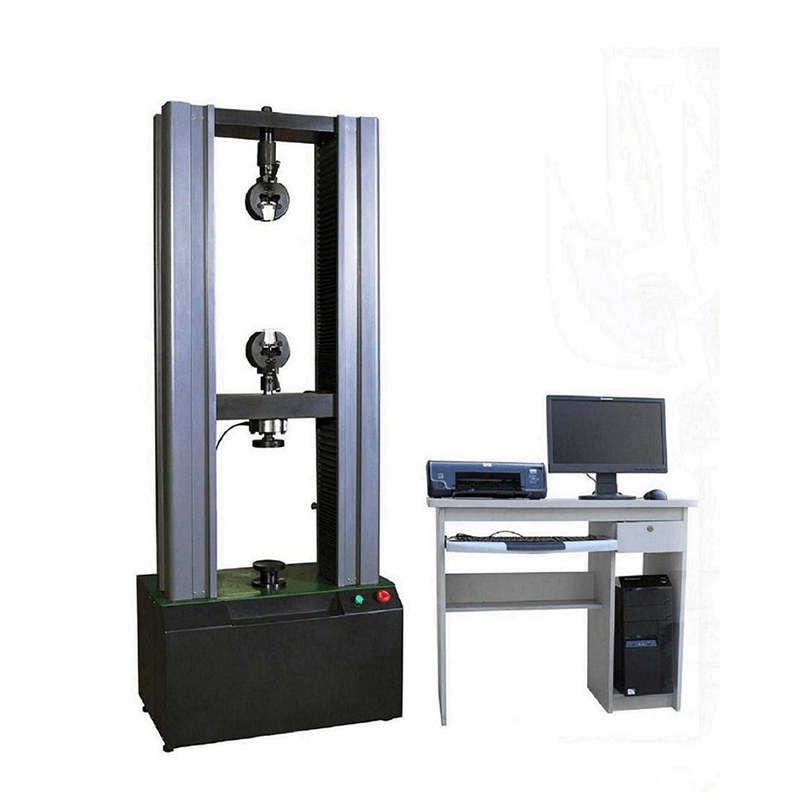

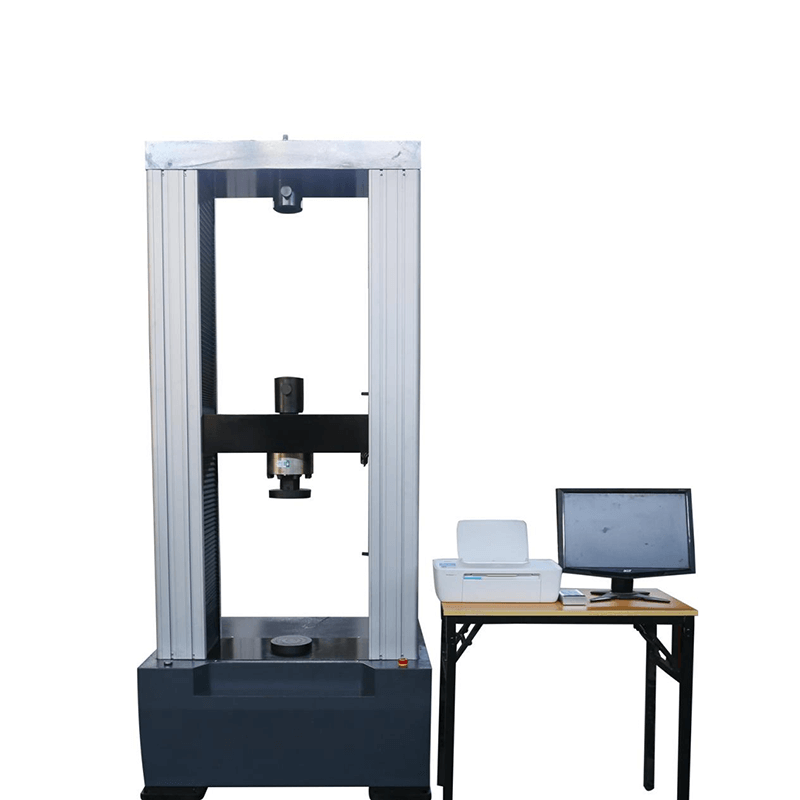

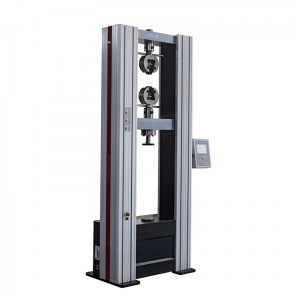

This testing machines is equipped with computer, printer, and general test software, to give an accurate determination of metal the material tensile strength, yield strength, the provisions of non-proportional extension strength, elongation, elastic modulus mechanical properties. Test results can print (force - displacement, force - deformation, stress - displacement, stress - deformation, force - time distortion - time) six kinds of curves and related test data, with the software self-test function that can self-diagnose problems. It is ideal testing equipment for the industrial and mining enterprises, scientific research units, universities, engineering quality supervision station. They are perfect testing instrument project quality testing section, universities and colleges, research institution and industrial and mining.

Specification

|

Select model |

WDW-50D |

WDW-100D |

|

Maximum test force |

50KN 5 tons |

100KN 10tons |

|

Test machine level |

0.5 level |

|

|

Test force measurement range |

2%~100%FS |

|

|

Relative error of test force indication |

Within ±1% |

|

|

Relative error of beam displacement indication |

Within ±1 |

|

|

Displacement resolution |

0.0001mm |

|

|

Beam speed adjustment range |

0.05~1000 mm/min (arbitrarily adjusted) |

|

|

Relative error of beam speed |

Within ±1% of the set value |

|

|

Effective stretching space |

900mm standard model (can be customized) |

|

|

Effective test width |

400mm standard model (can be customized) |

|

|

Dimensions |

720×520×1850mm |

|

|

Servo motor control |

0.75KW |

|

|

power supply |

220V±10%; 50HZ; 1KW |

|

|

Machine weight |

480Kg |

|

|

Main configuration: 1. Industrial computer 2. A4 printer 3. A set of wedge-shaped tension clamps (including jaws) 5. A set of compression clamps Non-standard fixtures can be customized according to customer sample requirements. |

||

Key Features

1. Rigid floor-standing frame loading structure with upper space for tensile and lower one for compression and bending test

2. Precise ball screws withstand the whole loading with long-life use and compact layout.

3. Speed control system is set under the table and comprises the synchronous toothed belt and pulley for high-efficient transmission, which are featured with low noise and maintenance free.

4. Fixed crossbeam as upper ones, and sits above the frame and with middle crossbeam as loading beam with smooth travel when testing . The high-accuracy sensor is installed below the crossbeam.

5. Load automatic withstanding,, stress, strain control, cycle control and self programming.

6. High precision load sensor for guarantee accurate and stable measure

7. Wide crossbeam travel speed from 0.05 ~ 500mm / min

8. Overload protection: as test force exceeds 2%-5% of the maximum test force of each file, overload protection, it will stop.

Standard

ASTMA370, ASTME4, ASTME8, ASTME9, ISO6892, ISO7438, ISO7500-1, EN10002-4, GB/T228-2002, GB 16491-2008, HGT3844-2008 QBT 11130-1991, GB13-22-1991, HGT 3849- 2008,GB6349-1986, GB/T 1040.2-2006, ASTM C165, EN826, EN1606, EN1607, EN12430 etc.