Application

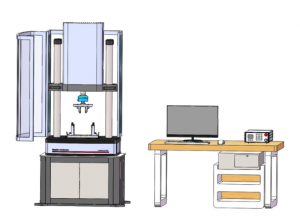

Simplified, highly intuitive platform for dynamic and static testing

Aims to promote innovation in the testing process of materials and components, provide excellent precision and unprecedented ease of use;

Cleverly designed to enhance your laboratory performance

With its simple, clean and platform-based design, this test platform provides you with all the advantages of electrical motion, easy to install, simple to operate, and ultra-quiet; the result is that you have a powerful and highly applicable test system , To provide you with all the performance and convenience you want!

Specifications

|

Model |

2000 |

5000 |

10000 |

20000 |

|

Maximum test force KN (dynamic and static) |

±2000N |

±5000N |

±10000N |

±20000N |

|

Load frame |

Two-pillar platform type, electric beam adjustment, |

|||

|

Effective width of column mm |

555 |

555 |

600 |

600 |

|

Test space mm |

550 |

550 |

750 |

750 |

|

Test force measurement range |

Dynamic 2%~100%FS |

|||

|

Force accuracy and fluctuation |

Better than the indicated value by 1%; the amplitude fluctuation is not more than ±1% F.S for each file |

|||

|

Test force resolution |

1/500000 |

|||

|

Test force indication accuracy |

Dynamic ±1%; static 0.5% |

|||

|

Displacement measurement range |

150mm(±75mm) |

|||

|

Displacement measurement resolution |

0.001mmm |

|||

|

Accuracy of displacement indication |

Indication accuracy from 1% within ±0.5% FS |

|||

|

Deformation |

Indication accuracy from 2%, within ±0.5% |

|||

|

Frequency Range |

Standard machine 0.1-10HZ |

|||

|

Main waveform |

Sine wave, pulse wave, square wave, sawtooth wave, random wave |

|||

|

Assistive |

Compression aids, standard |

|||

|

Can be expanded, bent, cut, etc. (purchase separately) |

||||

Key Features

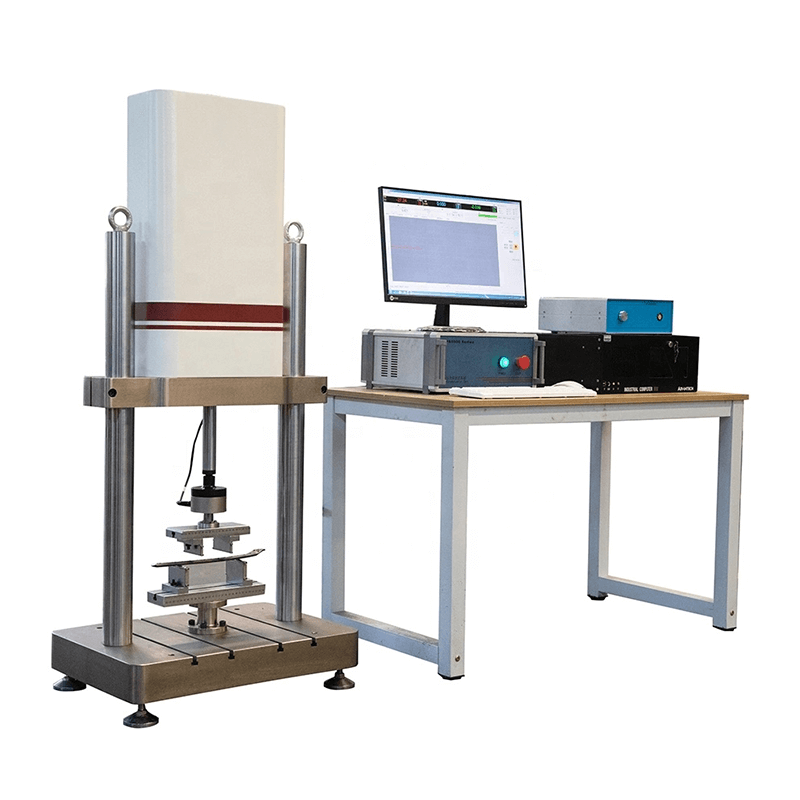

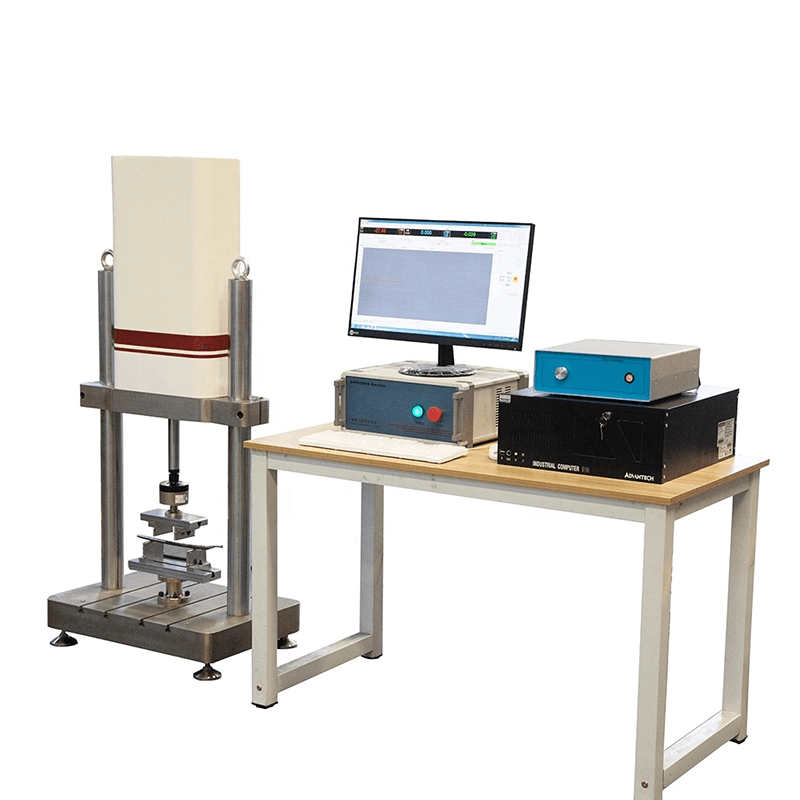

Machine Advantage: No matter where your team works-laboratory, office, or traditional workshop, the equipment can be quickly installed and used without additional infrastructure, easy to connect, compact design, quiet operation, and low maintenance!

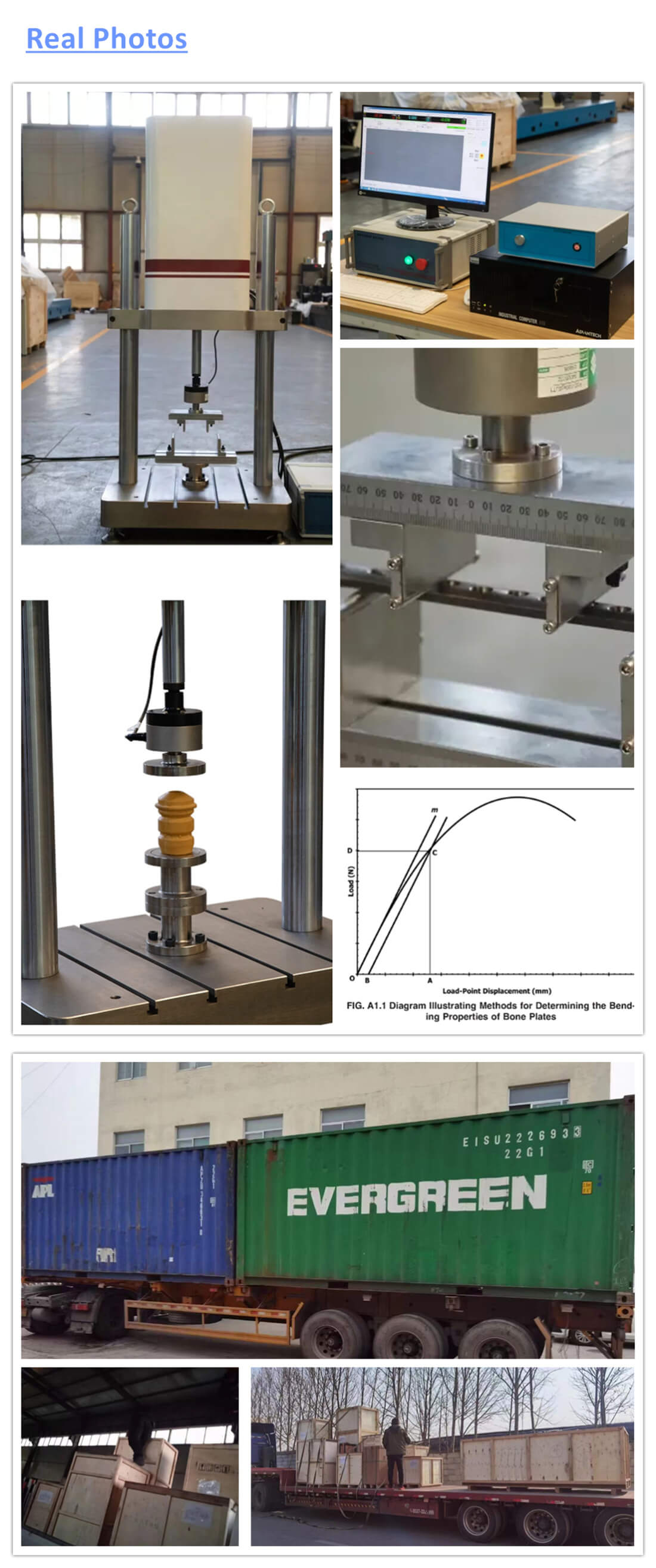

Performance advantage: The system can provide accurate results for dynamic and static testing, and is suitable for testing a large number of materials or components. The linear linear electric actuator provides highly repeatable dynamic and static drive. The large-diameter column and solid floor make the whole machine highly rigid. Prominent, with the imported dynamic force sensor, it ensures the accurate measurement of force; the built-in high-resolution digital encoder ensures accurate control and measurement of the sample position!

Software advantage: The system and software are designed for integrated use. The intuitive user interface and multi-task workflow greatly improve the ease and efficiency of test setup, execution, evaluation and reporting. It is suitable for fatigue, fracture, tension, compression, Bend and other test types!

Work efficiency advantage: The intelligent indication of the system status pays close attention to the test status, which reflects the safety of equipment operation and optimizes the human-machine coordination. The upper beam of the main body is manually locked, and the handle is ergonomically designed, which is convenient and easy to operate; use a standard T-shaped workbench for quick installation Various forms of test pieces make the entire test process simple!

Standards

1. GB/T 2611-2007 "General Technical Requirements for Testing Machines"

2. GB/T16825.1-2008 "Inspection of Static Uniaxial Testing Machine Part 1: Inspection and Calibration of Force Measuring System of Tension and/or Compression Testing Machine"

3. JB9397-2002 "Technical Conditions of Tension and Compression Fatigue Testing Machine"

4. GB/T 3075-2008 "Metal Axial Fatigue Test Method"

5. GB/T15248-2008 "Axial Constant Amplitude Low Cycle Fatigue Test Method for Metallic Materials"

6. HG/T 2067-1991 “Technical conditions of rubber fatigue testing machine”

The main components of the test equipment

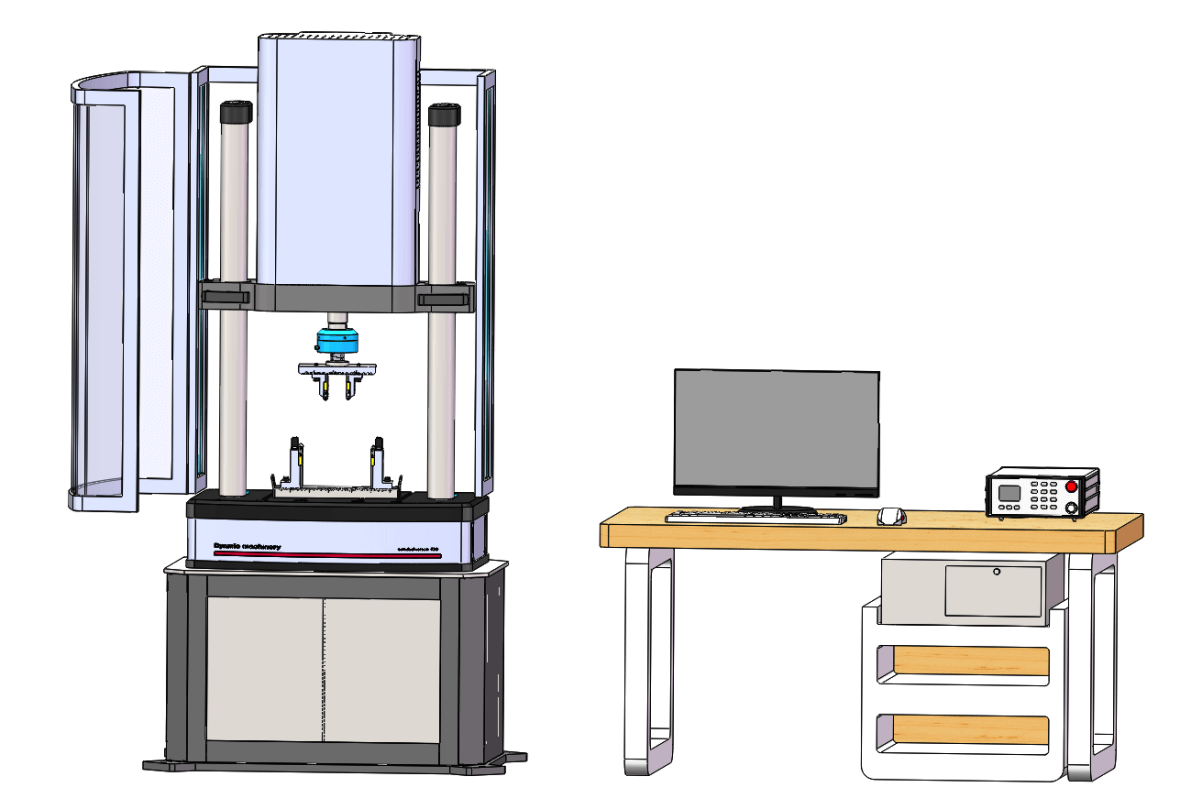

1. High-rigidity double-column portal type main loading frame;

2. Electric linear servo actuator

3. Full digital dynamic and static control system;

4. Chinese and English man-machine dialogue with lower computer operation application software;

5. Advantech industrial computers and office printers;

6. Test related conventional aids