Application

The drop hammer tester is suitable for various pipes (PVC-U water supply pipes, sewage pipes, low pressure water supply pipes, low pressure water pipes, core foam pipes, double-wall corrugated pipes, PE water supply pipes) and the impact resistance of plates Determination is also suitable for rigid plastic plates.

Key Features

1. SIMENS PLC controls and touch screen provide high reliability and versatility.

2. Automatic specimen feeding and automatic posting.

3. Frame structure is made of solid steel plate with high stability under impact.

4. Special design tools for support change.

5. Tup body is made of high strength steel plate with high impact resistance.

6. Use chain to lift striker with high precision in height.

7. Self-lock design for striker clamping.

8. Full-closed safety shield.

Specification

300J:

1) Maximum impact energy: 300J

2) Maximum impact height: 2m

3) The maximum combined mass of the drop hammer: 15KG±0.1%

4) Punch specification: A R=10mm

B R=20mm

C R=5mm

BB R=30mm

5) The deviation between the impact center and the fixture center is not more than 2mm

6) Electric kowtow lifting mechanism: maximum lifting force 20kgf

7) The maximum suction force of the traction electromagnet is not less than 20kgf

8) Pipe V-shaped pallet 200×300×25mm3

9) Plate ring type splint Ф40±1.0mm

Ф80±2.0mm

Ф130±2.5mm

10) Sample size: diameter 20-400mm

30000J:

1) Maximum impact energy 30000J

2) Host installation height ≤5.5m

3) Lifting height of drop hammer 2500mm

4) Impact speed ≥7m/s

5) Total mass error of falling weight ≤1%

6) Mass error of counterweight ≤±0.5%

7) Rockwell hardness of hammer blade and support jaw bearing surface >HRC56

8) The radius of curvature of the falling hammer blade R25.4±2.5mm

9) The radius of curvature of the support jaws R14.3±1.59mm

10) Support span 254+1.5mm

11) Deviation between the center line of the drop hammer blade and the center of the support span ±1.5mm

12) The deviation between the sample centering device and the center line of the sample notch ≤ 1.5 mm

13) The deviation of the lifting height of the falling weight from the standard value ≤ 1.5 mm

14) Specimen specification 305×76×(3~40)mm or steel pipe

15) External dimensions of testing machine 1600×2300×5500mm

16) Motor power 4kw

Standard

GB/T14152, GB/T14153, GB/T6112; GB/T5836, GB/T10002.1, GB/T10002.3, GB/T13664 , GB/T16800, GB/T18477

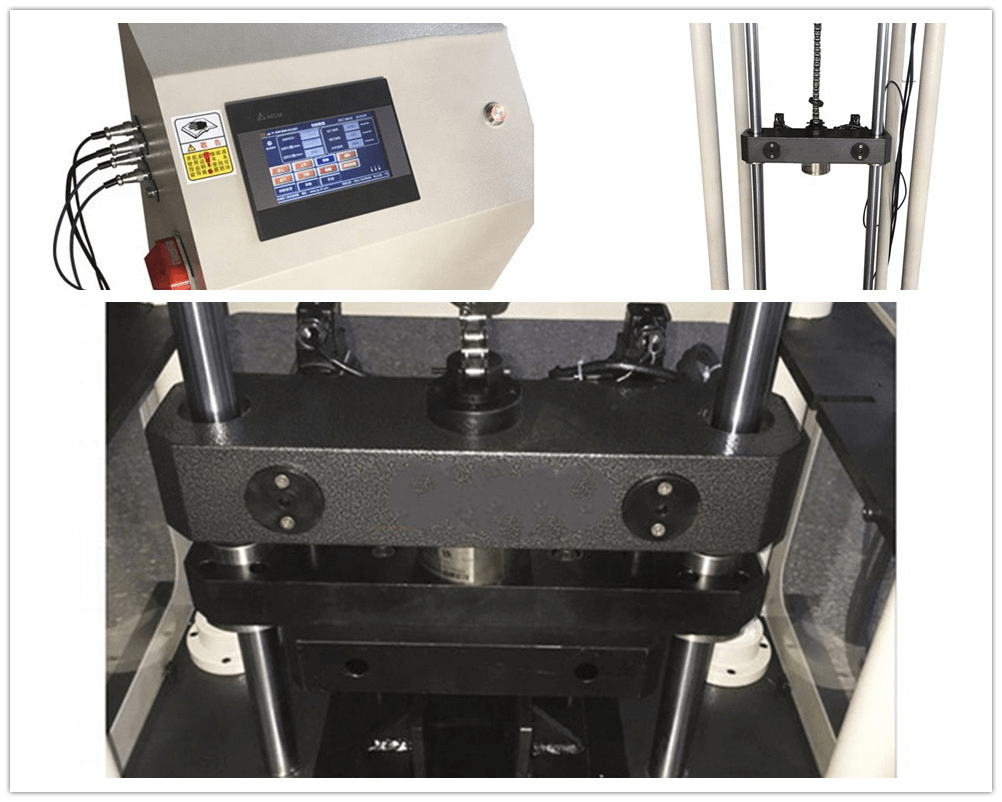

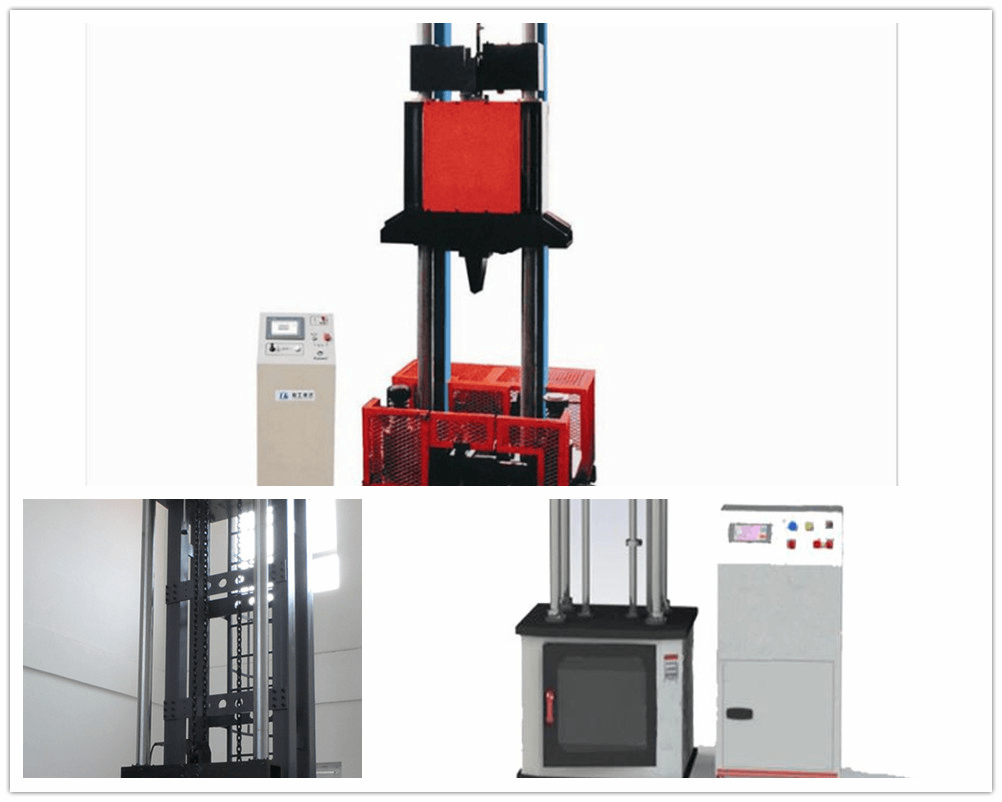

Real photos