Application

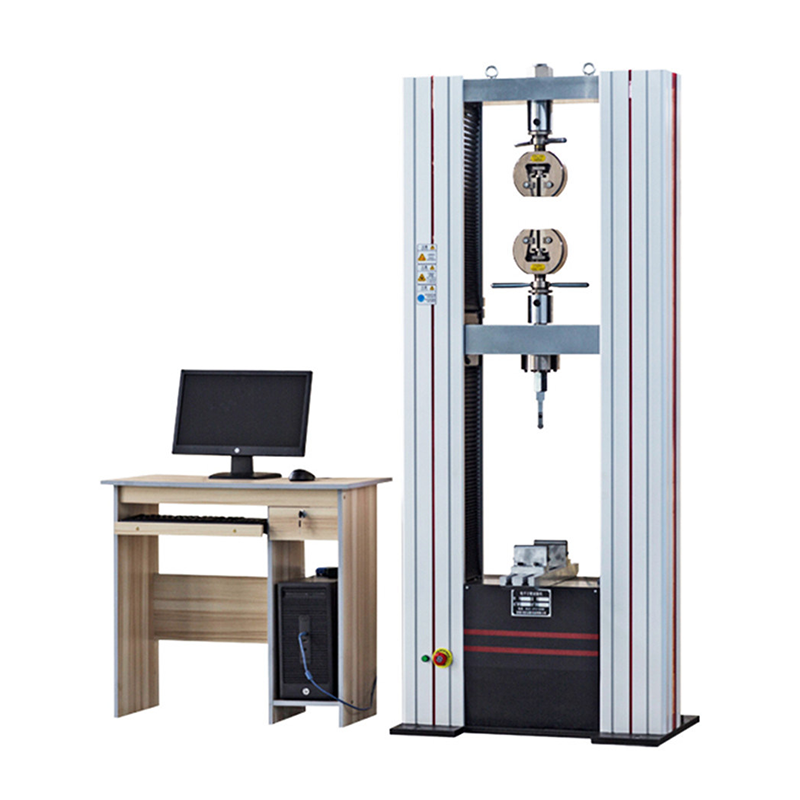

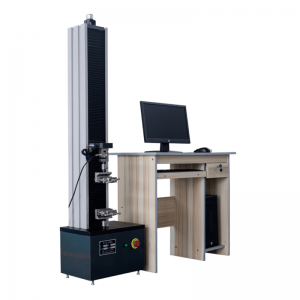

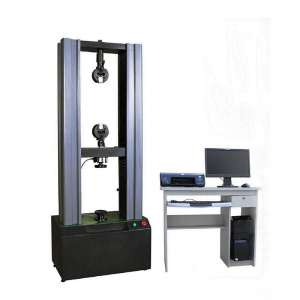

WDW series computer control electronic universal testing machine are suitable for tensile, compression, bending test of metal, steel, alloy, rubber, plastic, electrical wire and cable, composite, plastic profiled bar, waterproof roll, etc. They are essential testing instrument for quality testing section, university and college, research institution and industrial and mining enterprise.

Specification

|

Select model |

WDW-5D |

WDW-10D |

WDW-20D |

WDW-30D |

|

Maximum test force |

5KN 0.5 tons |

10KN 1 tons |

20KN 2 tons |

30KN 3 tons |

|

Test machine level |

0.5 level |

|||

|

Test force measurement range |

2%~100%FS |

|||

|

Relative error of test force indication |

Within ±1% |

|||

|

Relative error of beam displacement indication |

Within ±1 |

|||

|

Displacement resolution |

0.0001mm |

|||

|

Beam speed adjustment range |

0.05~1000 mm/min (arbitrarily adjusted) |

|||

|

Relative error of beam speed |

Within ±1% of the set value |

|||

|

Effective stretching space |

900mm standard model (can be customized) |

|||

|

Effective test width |

400mm standard model (can be customized) |

|||

|

Dimensions |

700×460×1750mm |

|||

|

Servo motor control |

0.75KW |

|||

|

power supply |

220V±10%; 50HZ; 1KW |

|||

|

Machine weight |

480Kg |

|||

|

Main configuration: 1. Industrial computer 2. A4 printer 3. A set of wedge-shaped tension clamps (including jaws) 5. A set of compression clamps Non-standard fixtures can be customized according to customer sample requirements. |

||||

Key Features

This machine adopts the most advanced and reliable load frame structure of ball screw electric mechanical universal testing machine, which equips alternating servomotor for driving crosshead, photoelectric encoder for displacement measure and high precision load cell to assure the high resolution of test.

Equipped with the computer &Software & printer, it can display, record, process and print the test results, and control test procedures as the set program and can draw test curves automatically in real time. Control software can automatically finger out routine data, such as tensile modulus of elasticity, extend rate after rupture, non-proportional extend strength Rp0.2, etc.

Standard

ASTM, ISO, DIN, GB and other international standards.