|

Info |

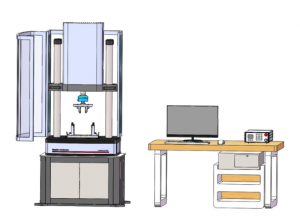

Machine Name |

CYC-686 Coordinate Measuring Machine |

|||||||||||

|

Recommend Configuration |

1 |

Frame |

Model |

CYC-686 |

Brand |

Qty |

|||||||

|

Control |

UCC |

Renishaw |

1 set |

||||||||||

|

2 |

Probe system |

Probe head |

PH10M Motorized indexing probe head |

Renishaw |

1 set |

||||||||

|

Probe |

SP25M scanning probe |

Renishaw |

1 set |

||||||||||

|

Styli |

- - |

Renishaw |

1 set |

||||||||||

|

Calibration Sphere |

φ25 |

- - |

1 set |

||||||||||

|

Resolution |

0.1mm |

Renishaw |

/ |

||||||||||

|

3 |

Computer |

PC |

Dual core 3.5G/8G/1T |

DELL |

1 set |

||||||||

|

Printer |

A4 Color inkjet Printer |

HP |

1 set |

||||||||||

|

4 |

Software |

NET.DMIS |

-- |

1 set |

|||||||||

|

5 |

Document | User manual soft copy |

- - |

1 set |

|||||||||

| NET.DMIS user manual soft copy |

- - |

1 set |

|||||||||||

|

Technical Parameter |

Length measuring system: Renishaw UK metal grating scaleResolution: 0.1mm

MPEE: MPEE≤1.5+L/300mm MPEP: MPEP≤1.5mm Measuring range: X×Y×Z 600mm×800mm×600mm Dimension: 1356mm×1940mm×2710mm Max. Load: 800 kg |

||||||||||||

|

Other |

Item |

Description |

Supplier |

Training form |

Person |

Days |

Remark |

||||||

|

Training |

CMM maintenance, operation and software use training |

Online training |

/ |

/ |

/ |

||||||||

|

Installation |

The installation, commissioning and final acceptance of the measuring machine at site shall be based on ISO 10360-2 coordinate measuring machine calibration specification. | ||||||||||||

|

Warranty |

Within one year from the date of shipment, all equipment hardware problems caused by seller shall be repaired by seller free of charge. | ||||||||||||

Write your message here and send it to us