Application

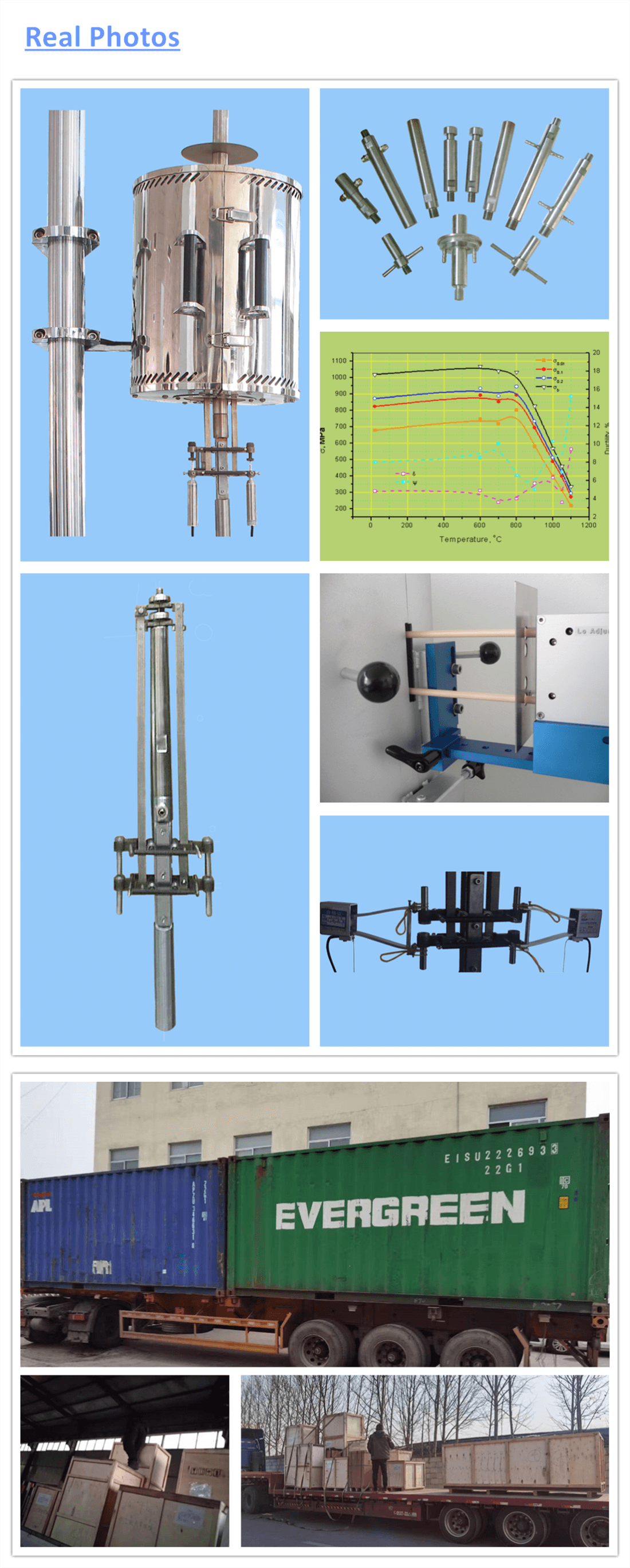

The electric furnace system consists of: high temperature furnace body, temperature measurement and control system, heating element, temperature measurement element, adjustable arm system, high temperature stretching fixture and connection accessories, high deformation measuring device, water cooling circulation system, etc.

Specification

| model |

HSGW—1200A |

|||

| Operating temperature |

300~1100℃ |

|||

| Long-term working temperature |

1000℃ |

|||

| Heating element material |

FeCrAl Resistance wire |

|||

| Furnace wire diameter |

φ1.2mm/φ1.5mm |

|||

| Temperature measuring element |

K/S type temperature measuring thermocouple (including special compensation wire) |

|||

| Soaking zone length |

100mm/150mm |

|||

| Number of heating body sections |

3 |

|||

| Number of temperature measuring points |

3 |

|||

| Temperature measurement sensitivity |

0.1℃ |

|||

| Temperature measurement accuracy |

0.2% |

|||

|

Temperature deviation |

Temperature(℃) |

Temperature deviation |

Temperature gradient |

|

|

300~600 |

±2 |

2 |

||

|

600~900 |

±2 |

2 |

||

|

>900 |

±2 |

2 |

||

| Inner diameter of furnace |

Diameter×Length:φ 90×300mm/φ 90×380mm |

|||

| Dimensions |

Diameter×Length:φ320×380mm/φ320×460mm |

|||

| Tensile grip | Round specimen

Flat specimen |

M12×φ5,M16×φ10 1~4mm,4~8mm |

||

| Extension measuring device |

Domestic bilateral extensometer / US imported Epsilon 3448 / German MF high temperature extensometer |

|||

| Temperature measurement and control system |

Xiamen Yudian 3 smart meters |

|||

| Operating Voltage |

380V |

|||

| Power |

Limit power when heating up 5KW |

|||

Feature

The instrument adopts advanced AI artificial intelligence adjustment algorithm, no overshoot, and has auto-tuning (AT) function.

The meter input adopts a digital correction system, with built-in non-linear correction tables for commonly used thermocouples and thermal resistances, and the measurement accuracy is up to 0.1 grade.

The output module adopts a single-channel phase-shift trigger output module, which has high control accuracy and good stability.

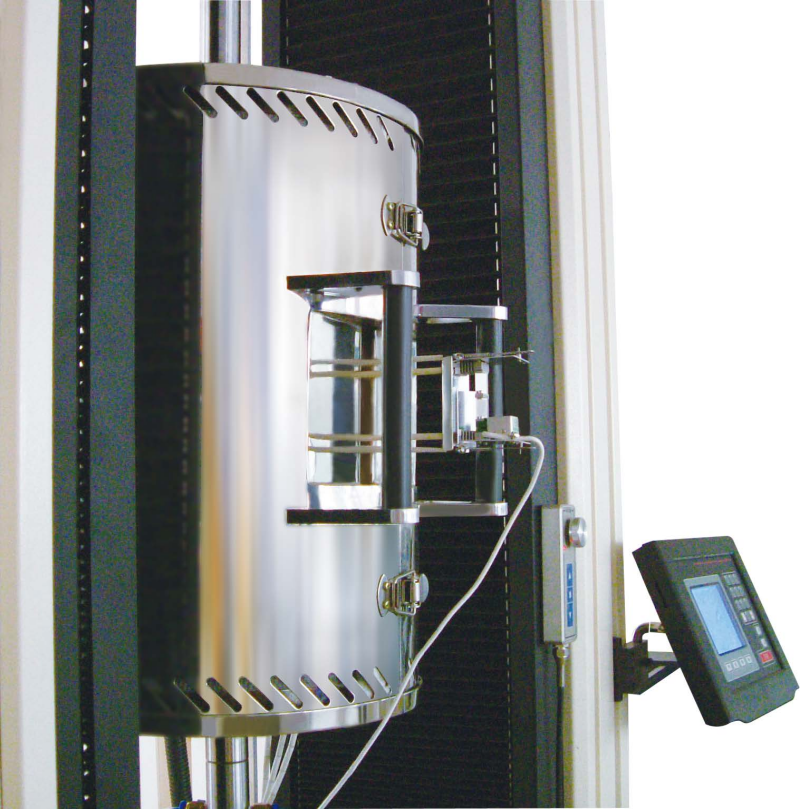

1. High temperature furnace body (domestic mechanical drawing device)

1.1High temperature furnace body (imported plug-in high temperature extensometer)

The furnace body adopts a split structure, the outer wall is made of high-quality stainless steel, and the inside is made of high-temperature alumina furnace tube. The furnace tube and the furnace wall are filled with thermal insulation ceramic fiber cotton, which has good insulation effect and small temperature rise on the surface of the furnace body.

There are grooves on the inner wall of the furnace tube. The iron-chromium-aluminum resistance wire is embedded in the furnace tube according to the length of the soaking zone and the temperature gradient and fluctuation requirements. The upper and lower holes of the furnace body have a small opening structure to reduce heat loss.

The rear part of the furnace body is equipped with hinges to facilitate the connection with the rotating arm or column.

2. The heating element is a spiral iron-chromium-aluminum resistance wire. The heating body is divided into three stages of control.

3. The temperature measuring element adopts NiCr-NiSi (K type) thermocouple, three-stage measurement.

4. High temperature fixture and connection accessories

According to the temperature requirements, the high temperature fixture and high temperature pull rod are made of K465 high temperature resistant alloy material.

The bar sample adopts threaded connection, and the samples of different specifications are equipped with one-to-one corresponding high-temperature fixtures.

The plate sample adopts the pin connection method, and the clamping thickness is downward compatible from the maximum specification: when clamping a sample with a small thickness, positioning pins of different specifications are added on both sides of the sample to ensure that the sample is on the tensile axis.

High temperature pull rod and high temperature fixture: Φ30mm (approximately)

The mechanical properties of K465 high temperature resistant alloy materials are as follows:

Water-cooled pull rod: Because this equipment is configured on the electronic universal testing machine, the load sensor is located above the high-temperature furnace, and the high-temperature furnace is close to the sensor. The water-cooled pull rod is equipped with a water-cooling system to prevent heat transfer to the load sensor and cause load measurement to drift.

5. Deformation measuring device

5.1 Adopt bilateral measurement method.

The high-temperature deformation measuring device is designed according to the specifications and gauge length of the sample. The rod-shaped sample deformation measuring device needs to correspond to the test specification one-to-one. The plate sample deformation measuring device is shared within the range of δ1~4mm, and shared within the range of δ4~8mm. set.

The deformation sensor adopts the strain-type average extensometer of Beijing Iron and Steel Research Institute, and directly outputs the average value of the deformation to the deformation measurement module. Its size is smaller than other types of sensors, and it is suitable for use in situations where the tensile test space is small.

5.2 High temperature deformation measurement extensometer adopts Epsilon 3448 high temperature extensometer imported from the United States

High temperature extensometer gauge length: 25/50mm

High temperature extension measurement range: 5/10mm

It is used in the heating system of high temperature furnace, adopts Epson's unique self-clamping design, and can provide a variety of test requirements

Optional.

It is suitable for measuring the deformation of metals, ceramics and composite materials at the high temperature generated by the heating system of the high-temperature furnace.

Fix the extensometer to the sample with a very light and flexible ceramic fiber thread, so that the extensometer is self-clamping on the sample. No high-temperature furnace mounting bracket is required.

Due to the role of the radiant heat shield and convection cooling fins, the extensometer can be used in an environment where the sample temperature reaches 1200 degrees without cooling.

5.3 High temperature deformation measurement extensometer adopts German MF high temperature extensometer

High temperature extensometer gauge length: 25/50mm

High temperature extension measurement range: 5/10mm

6. Water-cooling circulation system: It is composed of stainless steel water tank, circulation pump, PVC pipeline, etc.

7. Temperature measurement and control system

7.1 Composition of domestic temperature control instrument system

The temperature control system consists of temperature measuring elements (thermocouples), Xiamen Yudian 808 temperature intelligent instrument (PID adjustment, with AT function, the instrument can be equipped with 485 communication module and computer communication).