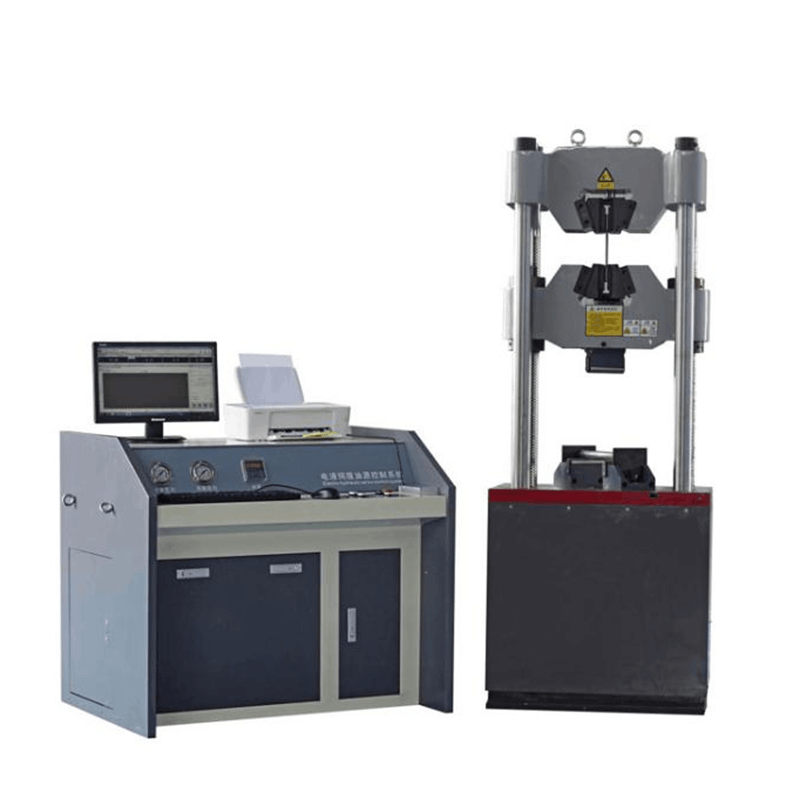

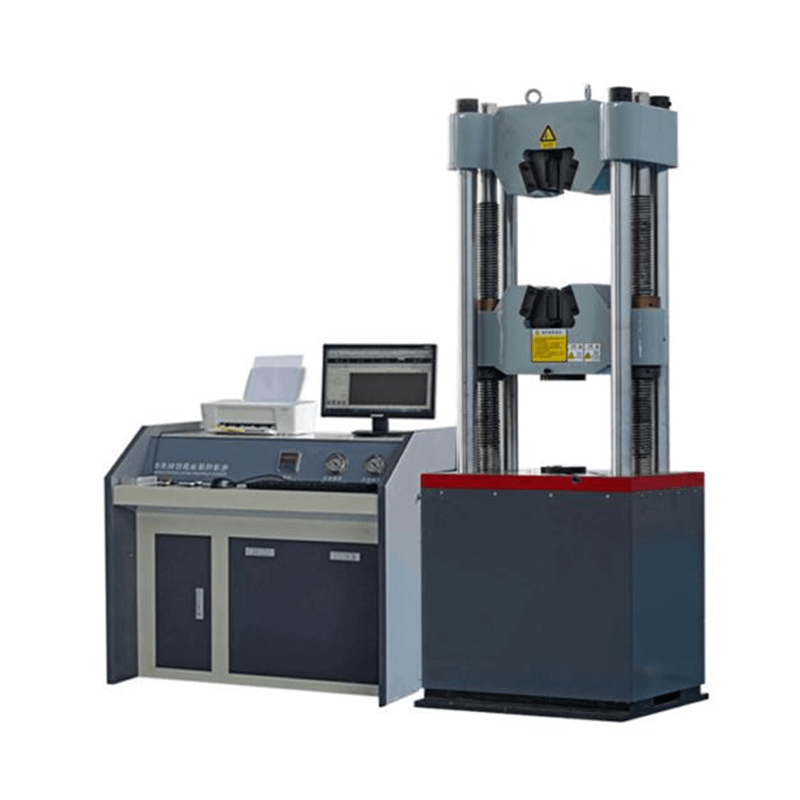

OEM Supply 300kn Hydraulic Universal Tester - WAW-1000D Microcomputer Controlled Electro-hydraulic Servo Universal Testing Machine – Chengyu Detail:

Application Field

WAW-1000 computer controlled servo hydraulic universal testing machine is mainly used to execute the tension, compression, bending, flexural etc. Test for metal materials. Attached with simple accessories and devices, it can be used to test wood, concrete, cement, rubber, and so on. It is very suitable for making test to different metal or nonmetal materials under high toughness and hardness against extreme big loading force.

Key Features

High-Tech, Low Noise

Humanized Industrial Design, Easy To Place And Transport

Security Protection System

Technical Engineer Support After Service

Manufacturers Direct Sales, Factory Prices

Sales In Stock, Fast Delivery Time

With EVOTest Software, can meet capable of tensile, compression, bending test and all kind of tests.

According to the Standard

It meets the requirements of the national standard GB/T228.1-2010 “Metal Material Tensile Test Method at Room Temperature”, GB/T7314-2005 “Metal Compression Test Method”, and complies with the data processing of GB, ISO, ASTM, DIN and other standards. It can meet the requirements of users and the standards provided.

Transmission System

The lifting and lowering of the lower crossbeam adopts a motor driven by a reducer, a chain transmission mechanism, and a screw pair to realize the adjustment of the tension and compression space.

Hydraulic System

The hydraulic oil in the oil tank is driven by the motor to drive the high-pressure pump into the oil circuit, flows through the one-way valve, high-pressure oil filter, differential pressure valve group, and servo valve, and enters the oil cylinder. The computer sends a control signal to the servo valve to control the opening and direction of the servo valve, thereby controlling the flow into the cylinder, and realizing the control of constant velocity test force and constant velocity displacement.

|

Display Mode |

Full Computer Control and Display |

|

|

Model |

WAW-1000B |

WAW-1000D |

|

Structure |

2 Columns |

4 Columns |

|

2 Screws |

2 Screws |

|

|

Max.Load Force |

1000kn |

|

|

Test Range |

2%-100%FS |

|

|

Displacement Resolution(mm) |

0.01 |

|

|

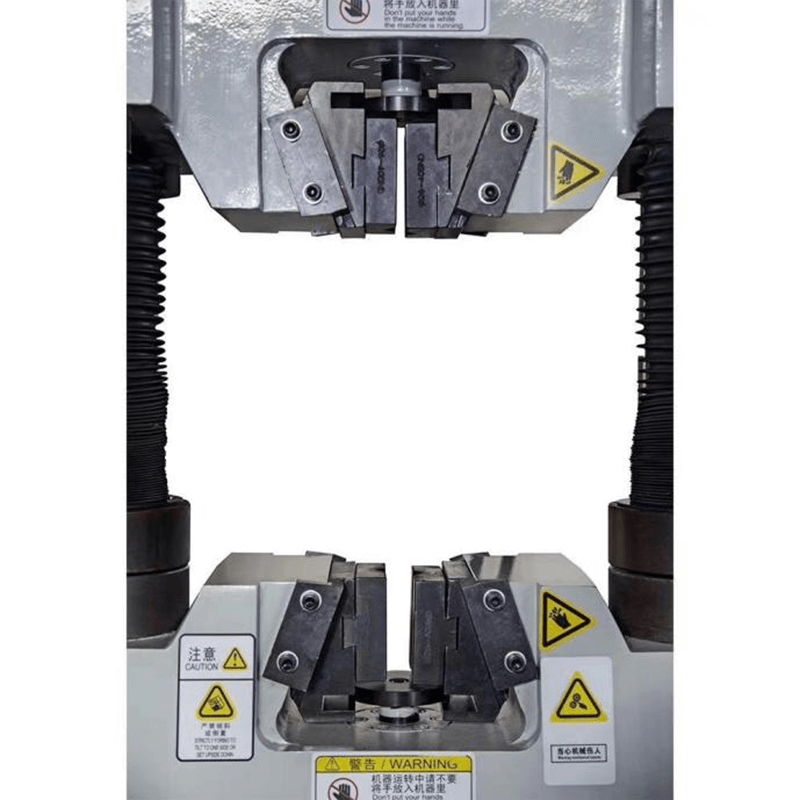

Clamping Method |

Manual clamping or Hydraulic clamping |

|

|

Piston Stroke(Customizable)(mm) |

200 |

|

|

Tensile Space(mm) |

670 |

|

|

Compression Space(mm) |

600 |

|

|

Round Specimen Clamping Range(mm) |

Φ13-50 |

|

|

Flat Specimen Clamping Range(mm) |

0-50 |

|

|

Compression Plate(mm) |

Φ200 |

|

Related Product Guide:

It adheres on the tenet "Honest, industrious, enterprising, innovative" to acquire new solutions continuously. It regards prospects, success as its personal success. Let us build prosperous future hand in hand for OEM Supply 300kn Hydraulic Universal Tester - WAW-1000D Microcomputer Controlled Electro-hydraulic Servo Universal Testing Machine – Chengyu , The product will supply to all over the world, such as: Argentina, Indonesia, Atlanta, Our products are mainly exported to Southeast Asia, the Middle East, North America and Europe. Our quality is surely guaranteed. If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.