Hot New Products Pendulum Impact Testing Equipment - JBW-150/300/500/750H Microcomputer Controlled Metal Pendulum Impact Testing Machine – Chengyu Detail:

Application

The machine can be used for the determination of anti-impact performance of metal materials when it is under dynamic loading, thus judged the quality of materials under dynamic loading. It is applicable for the laboratory, which does continuous compact tests, metallurgy, machinery manufacturing, and other industries.

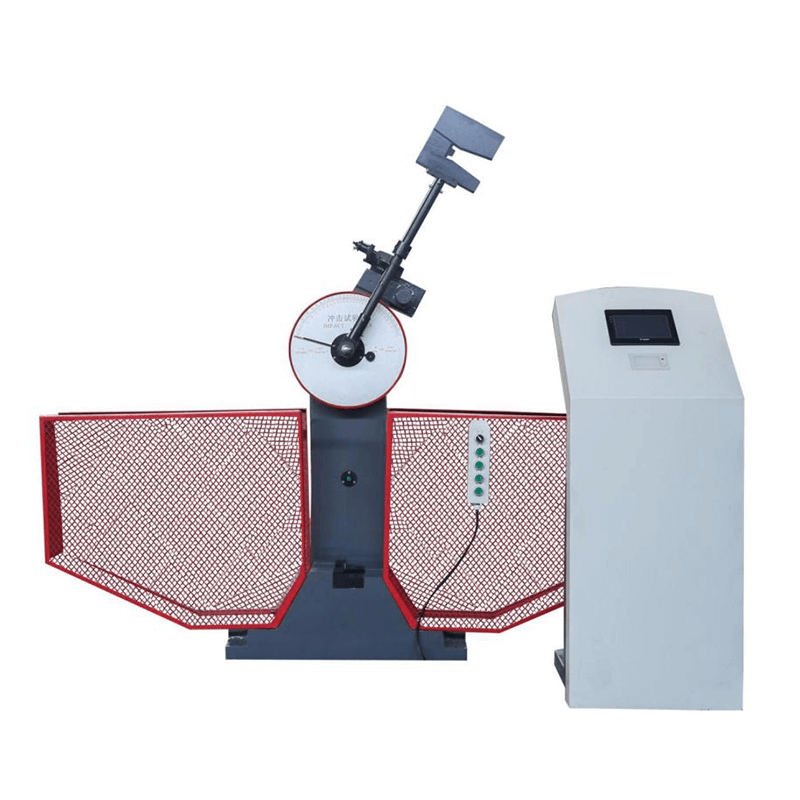

Key Features

(1) Main frame and foundation is integration, good stiffness and high stability.

(2) Axle of rotation adopts simple strut-beam, good stiffness, simple and reliable structure and high precision.

(3) Round pendulum makes wind resistance to mini.Impact knife adopts wedge block to compress and install.It is easy to exchange.

(4) Suspension pendulum device adopts hydraulic buffer to avoid damage and low noise when hang pendulum.It extends service life and improves safety.

(5) This machine adopts reducer to transport. Its structure is simple, easy to install and maintain, long service life and low breakdown rate.

(6) Three kinds of display modes, they display at the same time.Their results can compare with each other to remove possible problems.

Specification

|

Model |

JBW-300H |

JBW-500H |

|

Maximum impact energy |

300J |

500J |

|

Effective scope of application |

30-240J(20%-80%FS) |

50J-400J(20%-80%FS) |

|

Optional pendulum |

150J/300J |

250J/500J |

|

Pendulum advance angle |

150° |

150° |

|

The distance from the axis of the pendulum shaft to the center of the strike |

750mm |

800mm |

|

Pendulum moment |

M300=160.7696N.m M150=80.3848N.m |

M=267.9492N.m M=133.9746N.m |

|

Impact velocity |

5m/s |

5.2m/s |

|

Anvil span |

40mm |

40mm |

|

Anvil fillet radius |

R1-1.5mm |

R1-1.5mm |

|

Anvil inclination angle |

11°±1° |

11°±1° |

|

Impact edge angle |

30°±1° |

30°±1° |

|

R2 Impact Blade |

2mm±0.05mm(Chinese standard) |

2mm±0.05mm(Chinese standard) |

|

R8 Impact Blade |

8mm±0.05mm(American Standard) |

8mm±0.05mm(American Standard) |

|

Impact blade width |

10mm-18mm |

10mm-18mm |

|

Impact knife thickness |

16mm |

16mm |

|

Meet the sample specifications |

10*10*55mm 7.5*10*55mm 5*10*55mm 2.5*10*55mm |

10*10*55mm 7.5*10*55mm 5*10*55mm 2.5*10*55mm |

|

Machine weight |

480Kg |

600Kg |

|

Rated current |

Three-term four-wire 380V 50Hz |

Three-term four-wire 380V 50Hz |

|

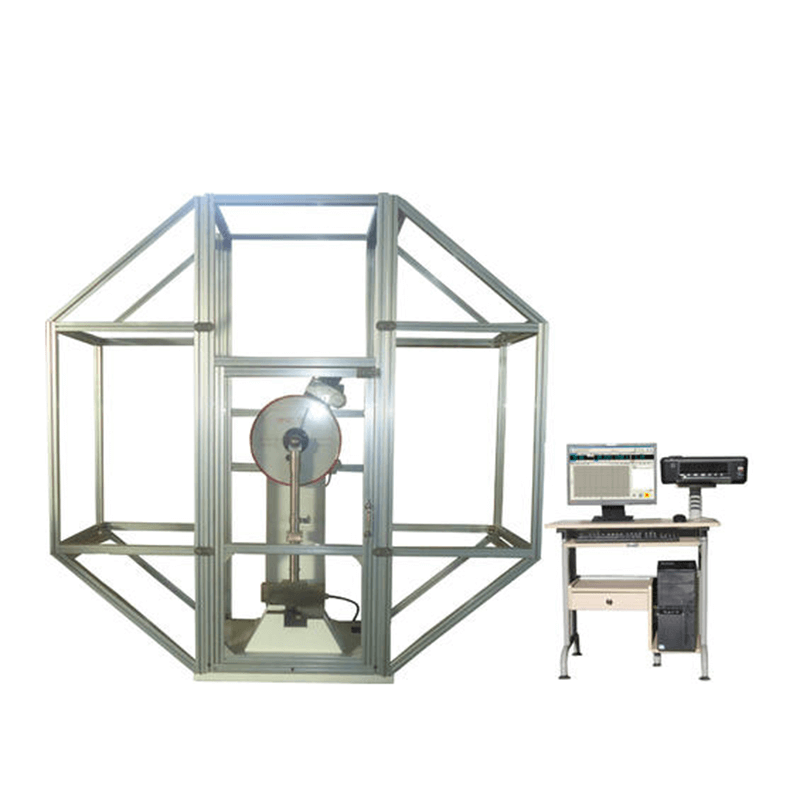

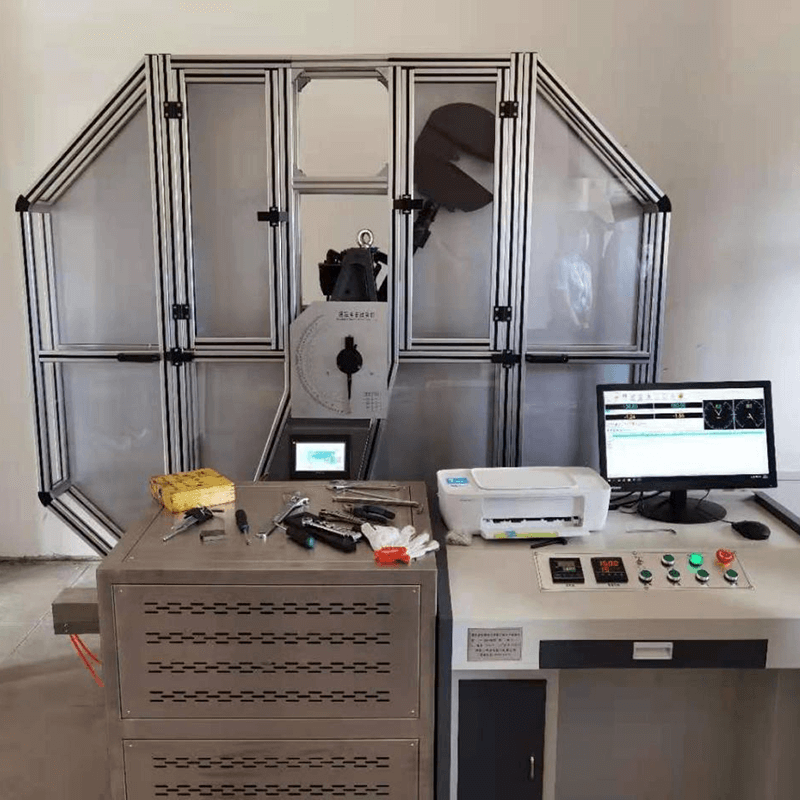

Main configuration: 1. Hand control operation box 2. Computer A4 printer 3. Aluminum alloy fully enclosed protective cover Technical indicators remarks: 1. Impact force sensor: range 50KN (100KN), accuracy better than ±1.0% (with amplifier accuracy) 2. AD converter: 16 bits, frequency response 1.25MHz 3. Signal amplifier: frequency response 1.5MHz 4. Rotary encoder: 3600 lines 5. Data acquisition card: imported high-performance data acquisition card, sampling rate ≥1.25M |

||

Standard

GB/T3038-2002 “Inspection of Pendulum Impact Tester”

GB/T229-2007 “Metal Charpy Notch Impact Test Method”

JJG145-82 “Pendulum Impact Testing Machine”

Related Product Guide:

We've got quite possibly the most state-of-the-art production gear, experienced and qualified engineers and workers, acknowledged top quality handle systems along with a friendly expert gross sales group pre/after-sales support for Hot New Products Pendulum Impact Testing Equipment - JBW-150/300/500/750H Microcomputer Controlled Metal Pendulum Impact Testing Machine – Chengyu , The product will supply to all over the world, such as: Mali, Dominica, United Arab Emirates, Since its foundation , the company keeps living up to the belief of "honest selling , best quality , people-orientation and benefits to customers. " We are doing everything to offer our customers with best services and best products . We promise that we'll be responsible all the way to the end once our services begin.

Good quality, reasonable prices, rich variety and perfect after-sales service, it's nice!